PLATE & FRAME HEAT EXCHANGERS

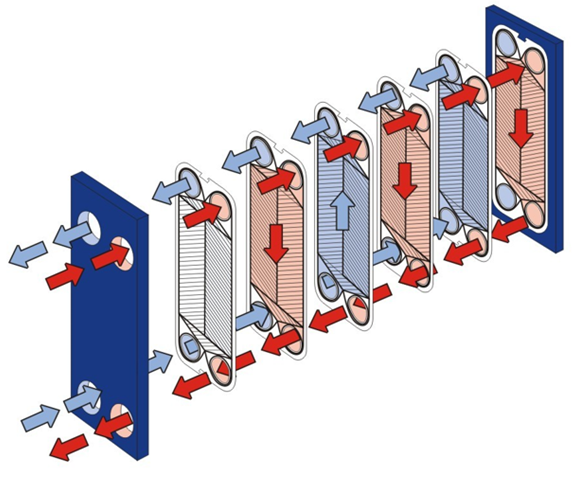

Working Principle

Channels are formed between the plates, and the corner ports are arranged in such a manner so as to allow the two media to flow through the alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Standard Materials:

- Frame plate: Epoxy Paint coated Carbon Steel / Mild Steel.

- Nozzles: Epoxy Paint Coated Carbon Steel / AISI 304 / AISI 316.

- Plates: AISI 304 / AISI 316.

- Gaskets: NBR / EPDM (Glued / Clip-on Glue less / Clip-on Glued).

- Frame stand: Epoxy Paint Coated Mild Steel.

- Hardware: HDGI / AISI 304.

Advantages of Plate & Frame Heat Exchangers:

Compactness: Plate & Frame heat exchangers use 80 percent less floor space and weigh a tenth as much as shell-and-tube units so they are easier, safer, faster, and more economical to ship, handle, and install.

Close temperature approach: Countercurrent flow takes exchange media in opposite directions across the plate for big temperature differences and small transfer surface requirements.

No cross-contamination: Media circuits are individually gasketed; the area between is vented to the atmosphere. Result: no inter-leakage.

Minimum fouling: Uniform flow and high fluid turbulence with the plate design promotes constant scrubbing action to reduce fouling.

Expandability: To enlarge a Plate & Frame heat exchanger, just loosen up the compression bolts and add the plates you need.

Easy Maintenance: Plate & Frame heat exchangers provide low fouling and good drainage. Connections are made to the front, piping stays in place when the units are opened. Moreover, Plate & Frame heat exchangers can be easily dismantled for inspection and cleaning (especially in food processing) and the plates along with gaskets are also easily replaceable as they can be removed and replaced individually.

Greater efficiency: Plate & Frame heat exchangers use less surface area to accomplish the same heat transfer as compared to shell-and-tube exchangers.

Flexibility: Changes can be made to heat exchanger performance by utilizing a wide range of fluids and conditions that can be modified to adapt to the various design specifications. These specifications can be matched with different plate corrugations.