RCT-SERIES, RECTANGULAR-TYPE, CROSS-FLOW, INDUCED DRAFT COOLING TOWERS

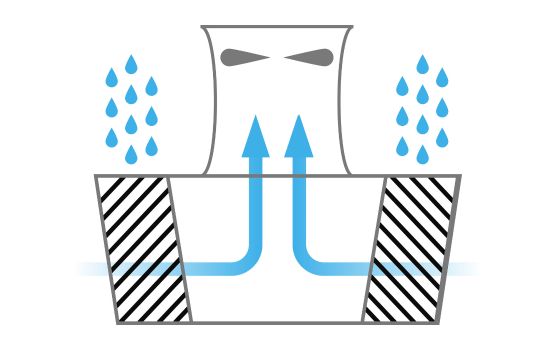

Working Principle

In cross-flow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. The air and water contact each other in cross patterns, because of the crossing of flows, the air does not need to pass through the distribution system. This permits the use of hot water flow via gravity through showering tray on the top of the tower right above the fill media. The trays are a standard of cross-flow cooling towers and are installed on all units.

Unique Selling Features of RCT-Series, Rectangular-Type, Cross-Flow, Induced Draft Cooling Towers by FRP Engineers

FANS: FRP RCT-Series Cooling Towers use Fiberglass Hollow Blades which are post-cure heat treated for longer service life. The Fans are energy efficient, and can also be prepared in Corrosion Resistant Fiberglass Material for special applications. Fiberglass Blades are fail-safe, and resistant to pitting by the chemically treated water used in cooling systems.

IN-FILLS: Vacuum thermoformed Rigid PVC In-fills with Integrated Drift eliminators are used. For high-temperature applications, Infills are used in Polypropylene Material.

STRUCTURE: Structural Components are in Fiberglass Material, whereas the internal supports are in HDGI or AISI 304.

WATER DISTRIBUTION: Water Distribution is open gravity type, and is done through Fiberglass Perforated Showering Trays. The trays have Water Diffusers installed on downside for even distribution of water on the In-Fills.

ELECTRICAL MOTORS: Energy Efficient IE2 and IE3 Motors of well-reputed brands are used in all FRP RCT-Series Cooling Towers.

HARDWARE AND FIXTURES: All internal fixtures and hardware are in AISI 304 Material for longer life against rust and corrosion.

AFTER-SALE SERVICE: Nationwide installations and presence of service network ensures quick support to our customers.